Phone

+86-18678773290The ZW Mixer Tank Semi Trailer is engineered for high-volume, on-road concrete delivery. It combines high-capacity mixing, precision-engineered structure, and smooth transport features in one robust solution. Designed to meet global construction needs, this trailer ensures concrete remains fresh, homogeneous, and ready for use upon delivery.

Large-capacity rotating drum (8-12m³ models available)

High-strength wear-resistant steel construction

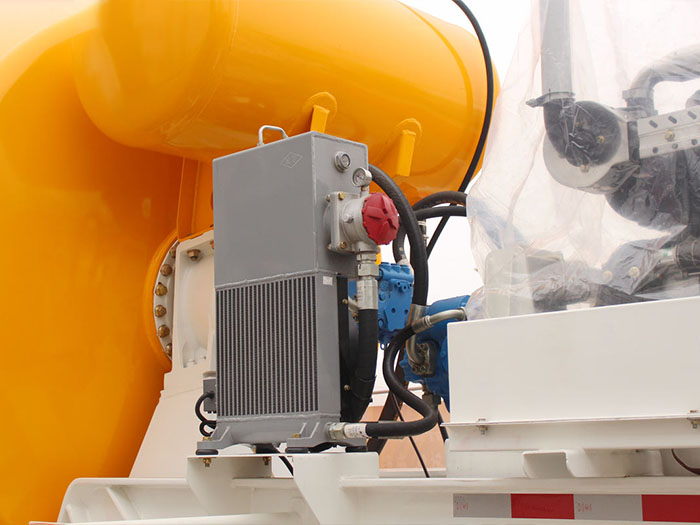

Hydraulic-driven drum with optimized spiral blade design

Reliable power take-off (PTO) or diesel auxiliary engine system

Rear discharge chute with adjustable angle

Anti-corrosion coating for extended service life

Compatibility with most 6x4 or 8x4 tractors

| Parameter | Specification |

|---|---|

| Mixing Volume | 8–12 cubic meters |

| Drum Material | Q345 high-tensile wear-resistant steel |

| Tank Thickness | 5 mm (body), 6 mm (spiral blades) |

| Dimensions | 10000–12000 mm (length) |

| Axles | 2 or 3, FUWA/BPW (optional) |

| Suspension System | Mechanical or Air Suspension |

| Tires | 12R22.5, 6 or 8 units |

| Landing Gear | JOST brand, two-speed operation |

| Discharge Speed | 0.6–1.2 m³/min |

| Rotation Speed | 0–14 rpm |

| Hydraulic System | Italy/Eaton hydraulic motor & pump |

| Painting | Anti-corrosion polyurethane finish |

Advantages: Why Choose ZW Mixer Tank Semi-Trailer?

The internal spiral blades are scientifically designed for maximum concrete fluidity. The rotating drum ensures consistent mixing during transport. This prevents concrete separation and slumping, even on long-distance routes.

Built from Q345 steel, the tank withstands heavy loads and abrasion. Every weld passes ultrasonic inspection. The reinforced chassis ensures long-term structural integrity, even on rough roads.

Operators can choose between PTO-driven systems or independent diesel engines. This provides unmatched flexibility in different truck-trailer combinations and geographic regions.

The trailer is engineered for ideal weight balance across axles. This helps reduce tire wear, improves fuel efficiency, and enhances road safety.

The discharge chute is manually adjustable. A ladder with anti-slip steps allows safe access for inspection. The hydraulic system is sealed and centralized for minimal leakage and quick troubleshooting.

The trailer complies with DOT, ADR, and ISO certifications. It is export-ready for markets across Africa, Southeast Asia, the Middle East, and Latin America.