Phone

+86-18678773290It has three core traits: strong heavy-load capacity, high unloading efficiency, and all-condition durability. So, it becomes a top solution in engineering logistics.

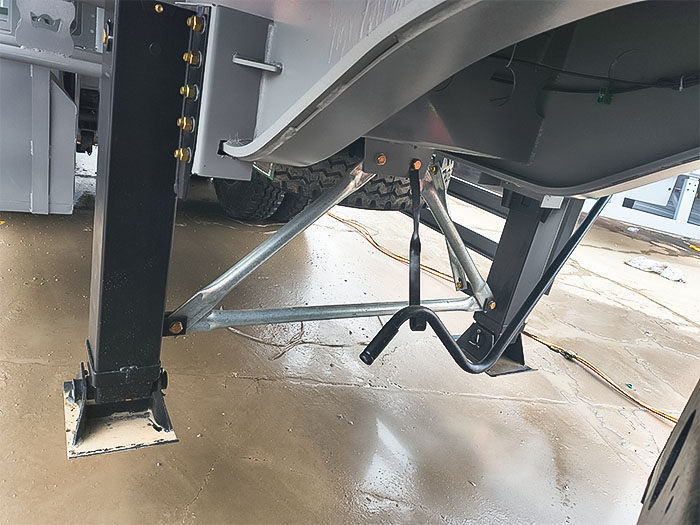

It adopts 3 heavy-duty special axles. Each axle has a rated load of 13 tons. Its total load capacity fits 40-55 m³ bulk materials. The capacity adjusts based on material density. The cargo box uses Q700 high-strength alloy steel. Its side plates are 6mm thick, and the bottom plate is 8mm thick. It has a “U-shaped body + 3D reinforcing ribs” structure. Its anti-deformation ability is 40% higher than conventional designs. This solves cargo box bulging and cracking under heavy loads. The standard inner size of the cargo box is 8.6m×2.55m×1.85m. Its volume reaches 40.5 m³.

It comes with 12.00R22.5 all-steel radial engineering tires. The tread depth is 24mm. Its off-road grip and wear life rise by 35%. The rims use lightweight forged aluminum alloy. They have high strength and reduce unsprung mass. It also has a standard ABS+EBS braking system. Braking response time is ≤0.3 seconds. The rear integrates high-brightness LED outline lights. It also has steering auxiliary lights and red-white reflective signs. This boosts visibility by 60% at night and in bad weather.

It has fast lifting speed and thorough unloading. It also has all-terrain passability. (3 axles are evenly distributed + wide-base tires.) This improves passability in muddy mining areas by 20%. Thus, material transportation efficiency is 25% higher than traditional equipment.