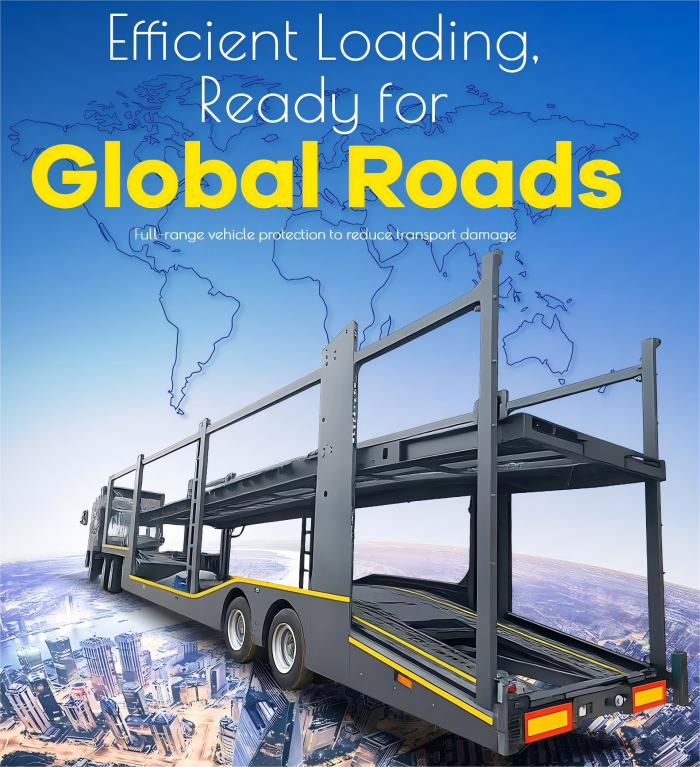

Car carrier trailers are specialized vehicles built specifically for moving commercial vehicles. These powerful haulers support the entire automotive logistics industry. Manufacturers design them with various lengths and structures to meet specific shipping needs. These trailers also go by names like auto transport trailers or vehicle haulers.

Core Structure and High-Quality Manufacturing

Modern car carriers use high-strength imported steel to reduce overall weight. Engineers build the main body using automatic submerged arc welding and CO2 gas shielded welding. This ensures a stable frame and a professional appearance. After welding, the vehicle undergoes shot blasting to eliminate internal stress. This process also improves paint adhesion for better durability.

The frame typically features a double-layer loading platform. The upper platform moves up and down using specialized lifting devices. Operators use hydraulic cylinders, pulleys, or manual hoists to adjust the height. This flexibility allows the trailer to carry various vehicle sizes. A single trailer can transport between 5 and 24 vehicles at once.

Main Classifications of Car Carrier Trailers

You can classify these trailers by their body structure or axle configuration. Each type offers unique benefits for different transport scenarios.

Body Structure Varieties

Skeleton Type: This model has no side panels or roof. It is lightweight, low-cost, and saves on fuel. However, it offers less protection for the cargo.

Semi-Enclosed Type: These trailers lack a top plate but have side protection. They balance cost-efficiency with basic cargo safety.

Fully Enclosed Type: These feature side panels, front panels, and a rear door. They protect cars from weather and debris perfectly. Furthermore, they can carry other types of freight safely.

Axle and Tire Configurations

Double-Axle Single-Tire: This design uses a concave bridge to lower the floor. Consequently, it creates more vertical space for taller vehicles.

Double-Axle Double-Tire: This is the most common model in the industry. It uses eight tires to provide superior load-bearing capacity.

Center-Axle Car Carriers: These newer models can reach 22 meters in length. They offer high economic benefits by carrying up to 10 cars.

Essential Safety and Loading Components

Safety is the top priority during long-distance vehicle transportation. Therefore, manufacturers include several specialized systems to secure the load.

First, operators must fix every car using specific methods. The wheel fixation method uses tire limiters and tighteners to prevent movement. Alternatively, the frame fixation method secures the car frame directly to the trailer. This prevents the car's suspension from bouncing during the trip.

Second, the trailer includes vital mechanical systems. Hydraulic systems control the lifting platforms precisely. Air brakes and suspension systems ensure a smooth ride. Additionally, many trailers feature hub cooling systems to prevent overheating. Standard equipment also includes toolboxes and spare tire racks.

Innovative Design for Easy Operation

Engineers focus on making these large vehicles easy to maintain. For instance, side doors allow quick access for technicians. At the back, pull-out ladders and ramps simplify the loading process. Moreover, some trailers use a three-segment design for the main frame. This allows owners to adjust the length for legal registration. Ultimately, these smart designs maximize space and improve efficiency for logistics companies.